Pain Points of Traditional Iron Cores: Hidden Issues Between Laminations

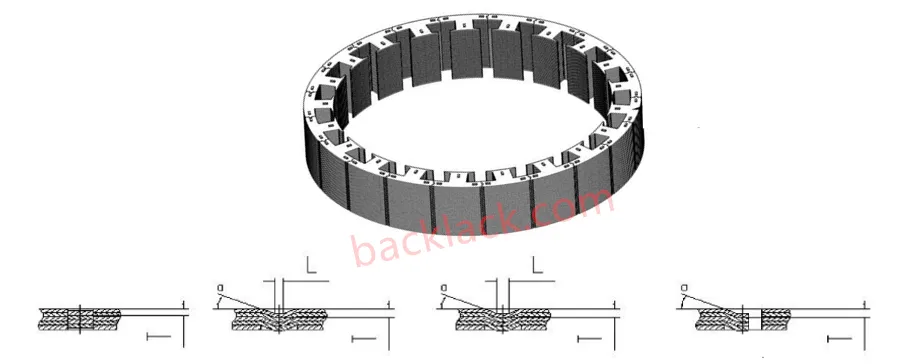

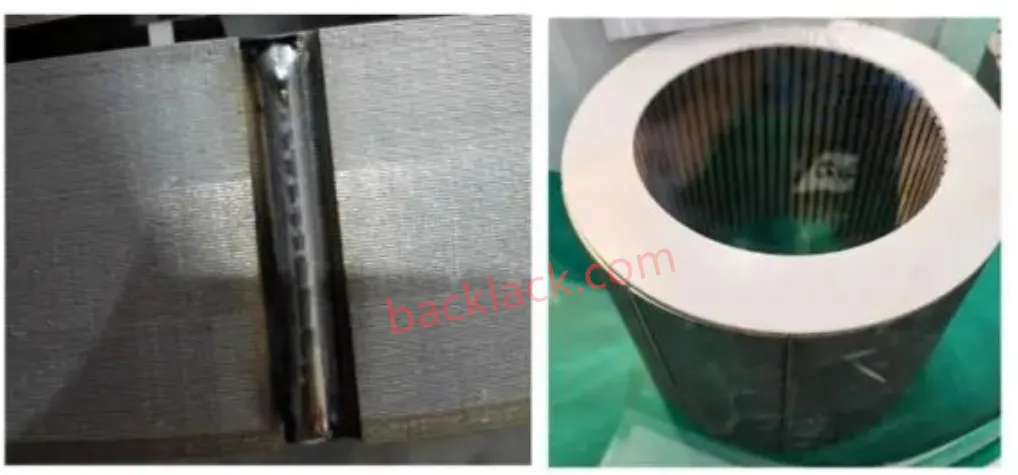

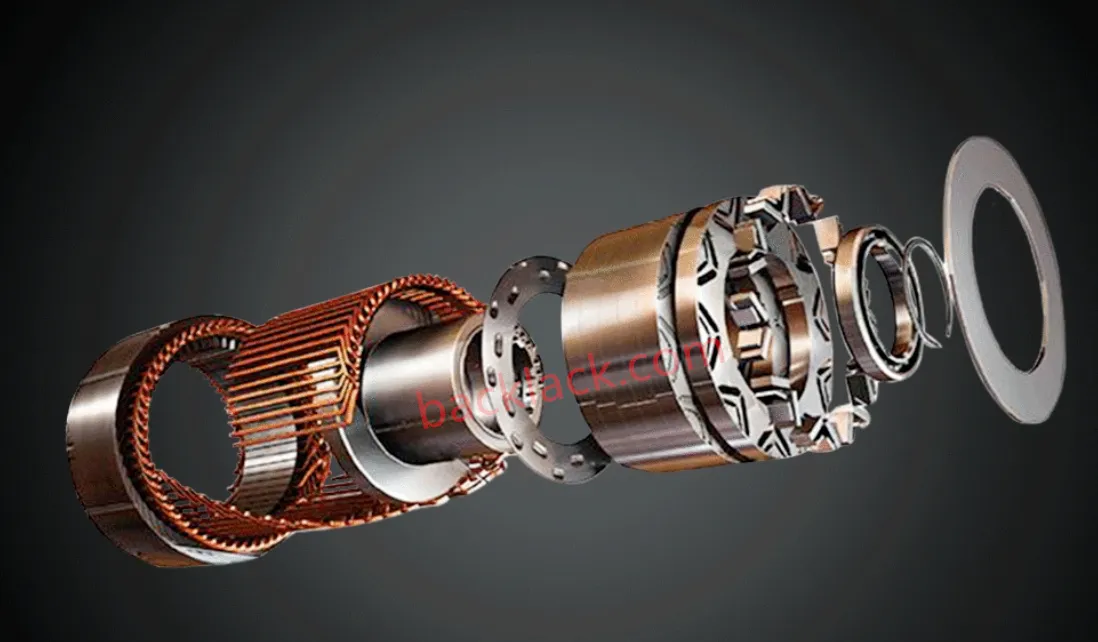

Motor iron cores are composed of hundreds or even thousands of stacked electrical steel sheets (silicon steel sheets). Their primary function is to form a magnetic circuit, guiding and amplifying the magnetic field. Traditionally, these laminations are secured by welding, riveting, or gluing with external glue.

However, these traditional methods have significant drawbacks:

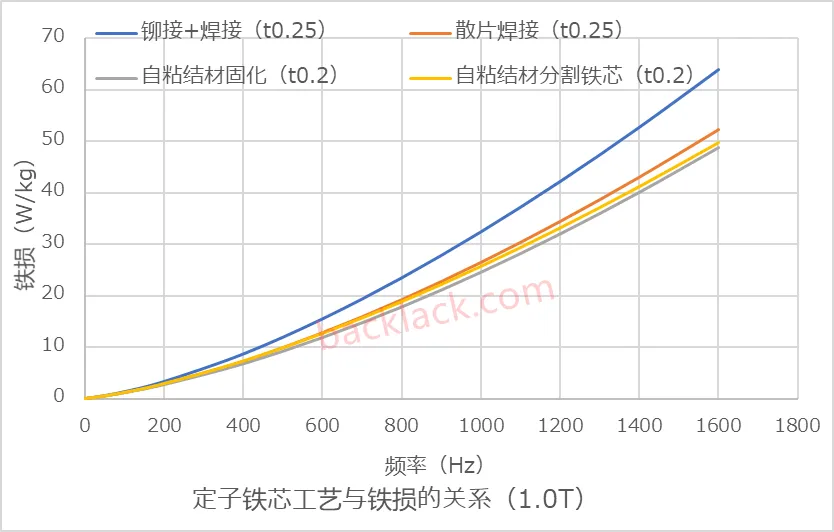

- Stress Induction: Welding and riveting can generate localized thermal and mechanical stresses, which degrade the material's magnetic properties, increase iron losses (eddy current and hysteresis losses), and reduce motor efficiency.

- Process Complexity: Additional bonding steps (such as gluing and curing) increase production steps, reduce automation, and drive up manufacturing costs.

- Reliability Risks: External glue can degrade and crack due to prolonged high temperatures and vibration, causing the laminations to loosen, leading to noise, vibration, and even structural failure.

These "pain points" directly hinder the development of motors with higher power density and efficiency.

Self-Bonding Core: From "External Binding" to "Self-Fusion"

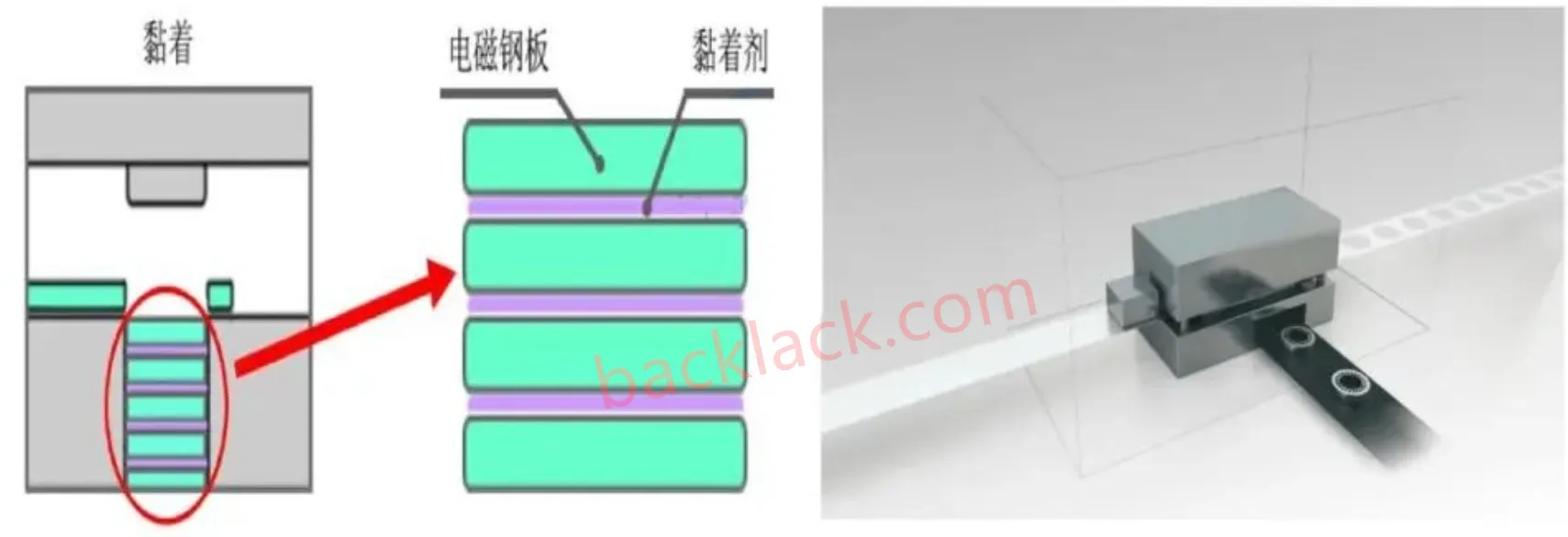

The core of self-bonding core technology is that it eliminates the need for external glue or mechanical connections. Instead, it utilizes a special coating on the surface of electrical steel to achieve a strong bond between laminates through physical or chemical reactions under specific temperature and pressure conditions.

Operating Principle:

- Special Coating: Before leaving the factory, the electrical steel strip is pre-coated with a heat- or pressure-sensitive insulating/bonding composite coating.

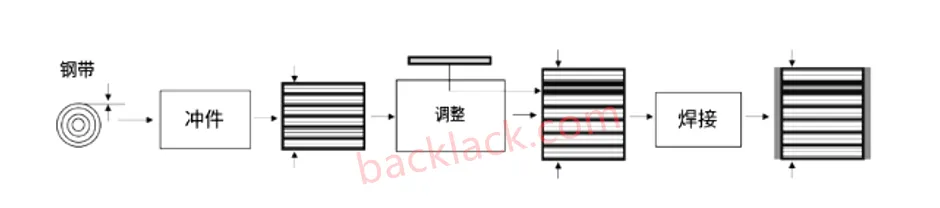

- Stamping: The strip is punched into the desired stator or rotor laminations.

- Lamination and Curing: After the laminations are neatly stacked, they are placed in a mold and heated and pressurized. During this process, the coating softens and flows due to the heat. Upon cooling, it forms a uniform, continuous bonding layer, "self-bonding" the laminations into a single unit.

Why is it the "key" to optimizing new energy vehicle power?

Self-bonding core technology brings multi-dimensional performance improvements to new energy vehicle motors:

-

Significantly Reduced Iron Loss and Improved Energy Efficiency

- It eliminates localized stress caused by welding/riveting, maintaining the excellent magnetic properties of electrical steel.

- The uniform bonding layer avoids the flux distortion caused by traditional point-type connections.

- Result: Iron loss can be reduced by 10%-20%, and motor efficiency can be increased by 1-3 percentage points. This means longer driving range for the same battery capacity, or lower battery costs for the same driving range.

-

Achieve Higher Power Density

- The high strength of the self-bonding structure effectively suppresses centrifugal forces at high speeds, allowing for higher motor speed designs.

- Compact structure, eliminating the need for additional connectors to occupy space.

- Result: Higher power output within the same volume, or miniaturization and lightweighting for the same power, creating conditions for optimizing vehicle layout and energy consumption.

-

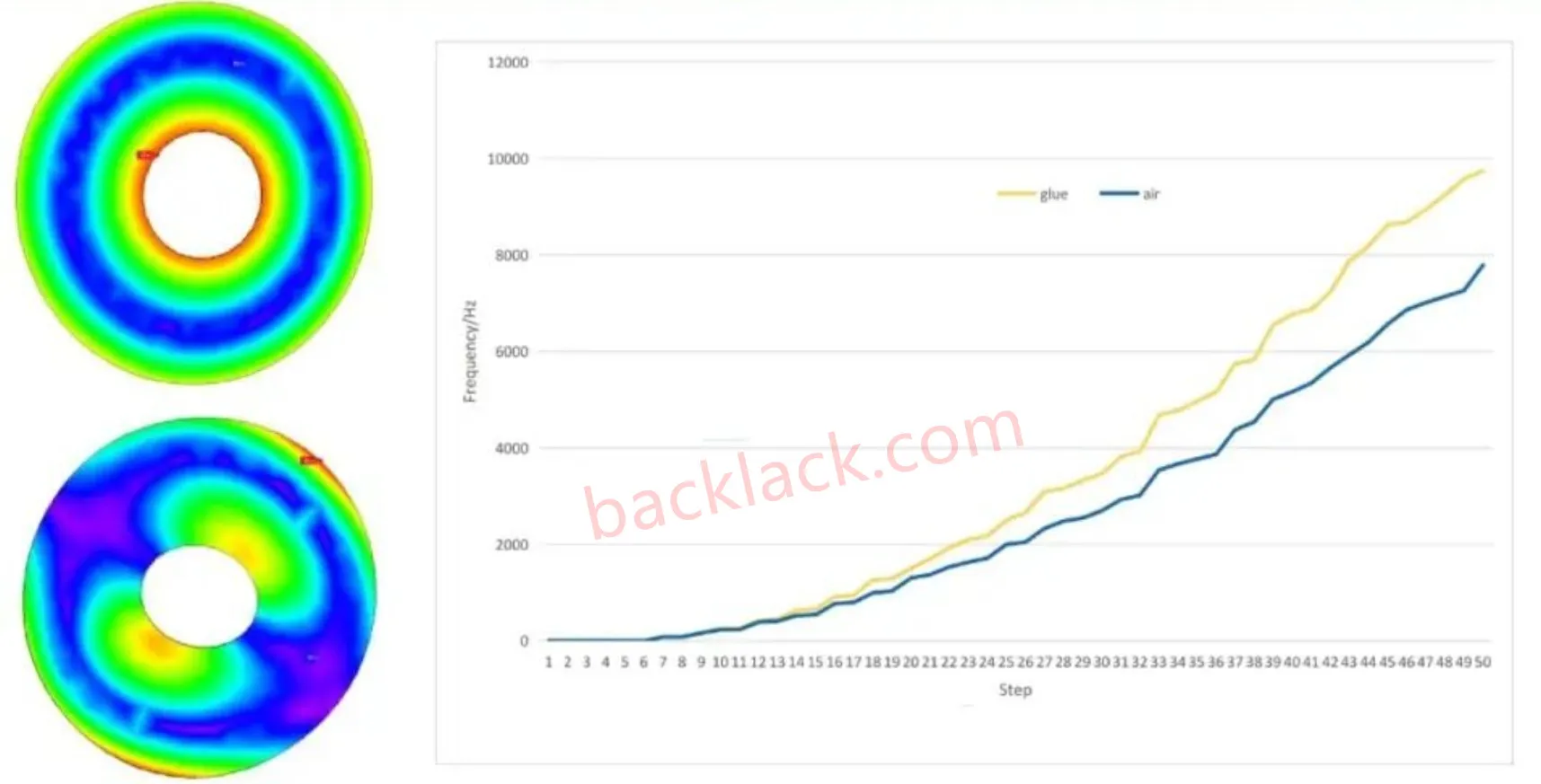

Improved NVH (Noise, Vibration, and Harshness) Performance

- The integrated bonding structure significantly enhances the rigidity of the core and effectively suppresses vibrations caused by electromagnetic forces.

- It eliminates the "buzzing" noise caused by micro-friction between the laminations.

- Result: The motor runs quieter and smoother, significantly improving driving comfort—a key selling point for high-end electric vehicles.

-

Simplified Manufacturing Process, Reduced Costs and Increased Efficiency

- Eliminating tedious steps such as gluing, positioning, and curing streamlines the production line.

- Making fully automated lamination easier improves production cycle time and consistency.

- Reducing the procurement and management costs of consumables such as glue.

- Result: Overall manufacturing costs can be reduced by 5%-15%, meeting the stringent cost control requirements of large-scale production of new energy vehicles.

-

Enhanced Environmental Resistance and Reliability

- The built-in coating provides a tighter bond with the substrate, offering superior resistance to high temperatures, humidity, and chemical corrosion than external glue.

- The bonding performance remains stable over a wide temperature range of -40°C to 180°C and in severe vibration environments.

- Result: longer motor life, lower failure rate, and meeting automotive-grade reliability standards.

Challenges and Future Outlook

Despite its significant advantages, self-bonded core technology still faces several challenges:

- Material Cost: Steel pre-coated with special coatings is more expensive than ordinary electrical steel.

- Process Control: The lamination temperature, pressure, and time parameters require extremely precise precision, requiring advanced equipment.

- Recycling: Disassembly of bonded cores is difficult, posing new challenges for material recycling.

Future Development Directions

- Coating Material Innovation: Developing coatings with lower costs and higher performance (e.g., higher temperature resistance and faster curing speed).

- Integration with Advanced Manufacturing: Exploring hybrid processes by integrating with technologies such as laser welding and powder metallurgy.

- Intelligent Production: Utilizing AI and big data to optimize lamination parameters and achieve quality prediction and control.

- Sustainability: Researching reversible bonding technologies or efficient recycling solutions.

Conclusion

Self-bonding iron core technology is more than a simple process replacement; it represents a systematic innovation from materials to structure. It precisely addresses the core requirements of new energy vehicles for motors: high efficiency, high power density, low noise, and low cost. With advances in materials science and maturing manufacturing processes, this technology is gradually becoming commonplace, moving from high-end models.

It is foreseeable that self-bonding iron cores will become standard equipment in new energy vehicle drive motors in the near future. They are not only key to power optimization but also a crucial fulcrum for the Chinese and global automotive industries to achieve technological advancement and industrial upgrades in the electrification race. When every watt of energy is meticulously calculated and every pound of weight is meticulously scrutinized, it is these seemingly small technological breakthroughs that converge into a tremendous force driving the future.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Soft Magnetic Alloy 1J22/1J50/1J79.