Introduction

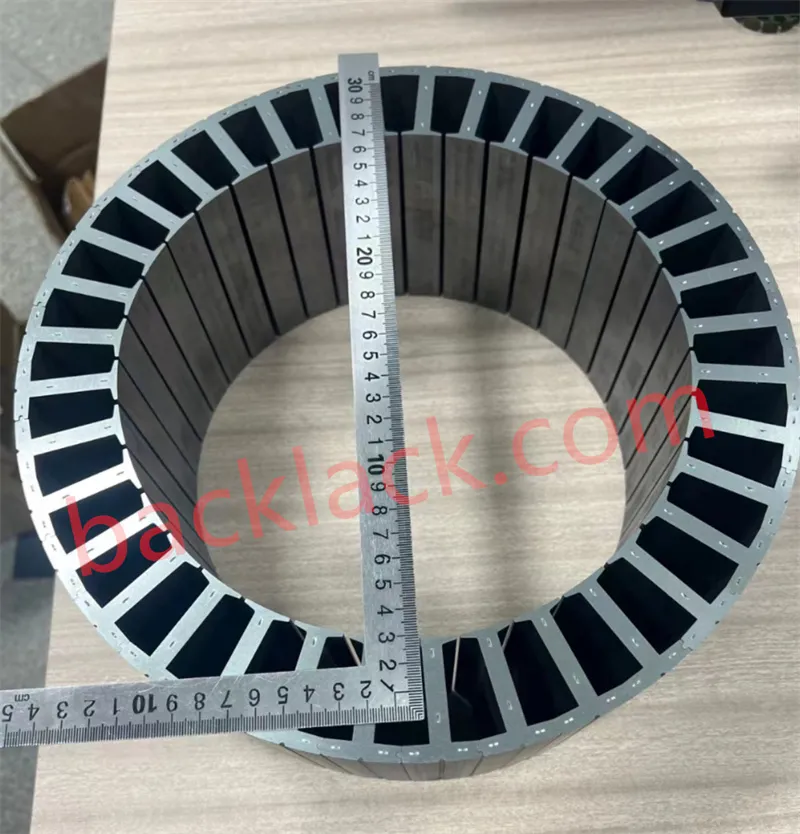

As a frontline customized stator core stamping supplier in China, we’ve been deeply embedded in the global motor lamination stack industry for over a decade. In an era where new energy vehicles (NEVs), high-efficiency industrial motors, and specialized smart equipment are driving demand for non-standard components, off-the-shelf motor lamination stacks can no longer meet clients’ unique performance and structural requirements.

Unlike mass-production-oriented manufacturers, our core strength lies in providing tailored stamping solutions for stator cores that align with each client’s motor design blueprint, performance targets, and production scale. This blog will unpack our customized stamping capabilities, core competitive advantages, real-world client success stories, and industry outlook—from the perspective of a China-based supplier that serves both domestic giants and global motor enterprises.

1. Why Custom Stator Core Stamping Is Non-Negotiable for Modern Motor Projects

1.1 The Limitations of Standard Lamination Stacks

Standard motor lamination stacks often fall short in addressing client-specific pain points:

- NEV drive motor developers: Need ultra-precision, low-core-loss stator cores to match 800V high-voltage architectures and extend vehicle range, but standard parts lack slot design flexibility

- Industrial motor upgraders: Must comply with China’s GB 18613-2022 IE5 energy efficiency standards while fitting legacy equipment frames, with no off-the-shelf options for non-standard dimensions

- Specialized equipment makers: Require lamination stacks compatible with amorphous alloys or nanocrystalline materials for aerospace/marine motors, a niche need ignored by mass producers

1.2 Our Custom Stamping Service Scope

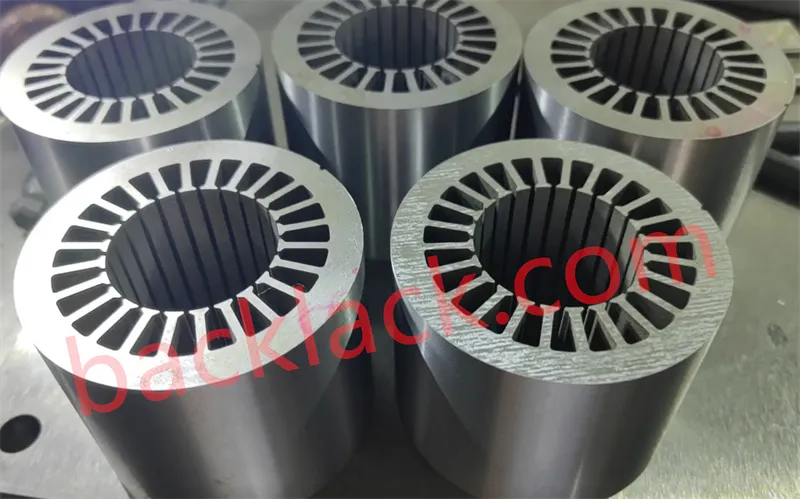

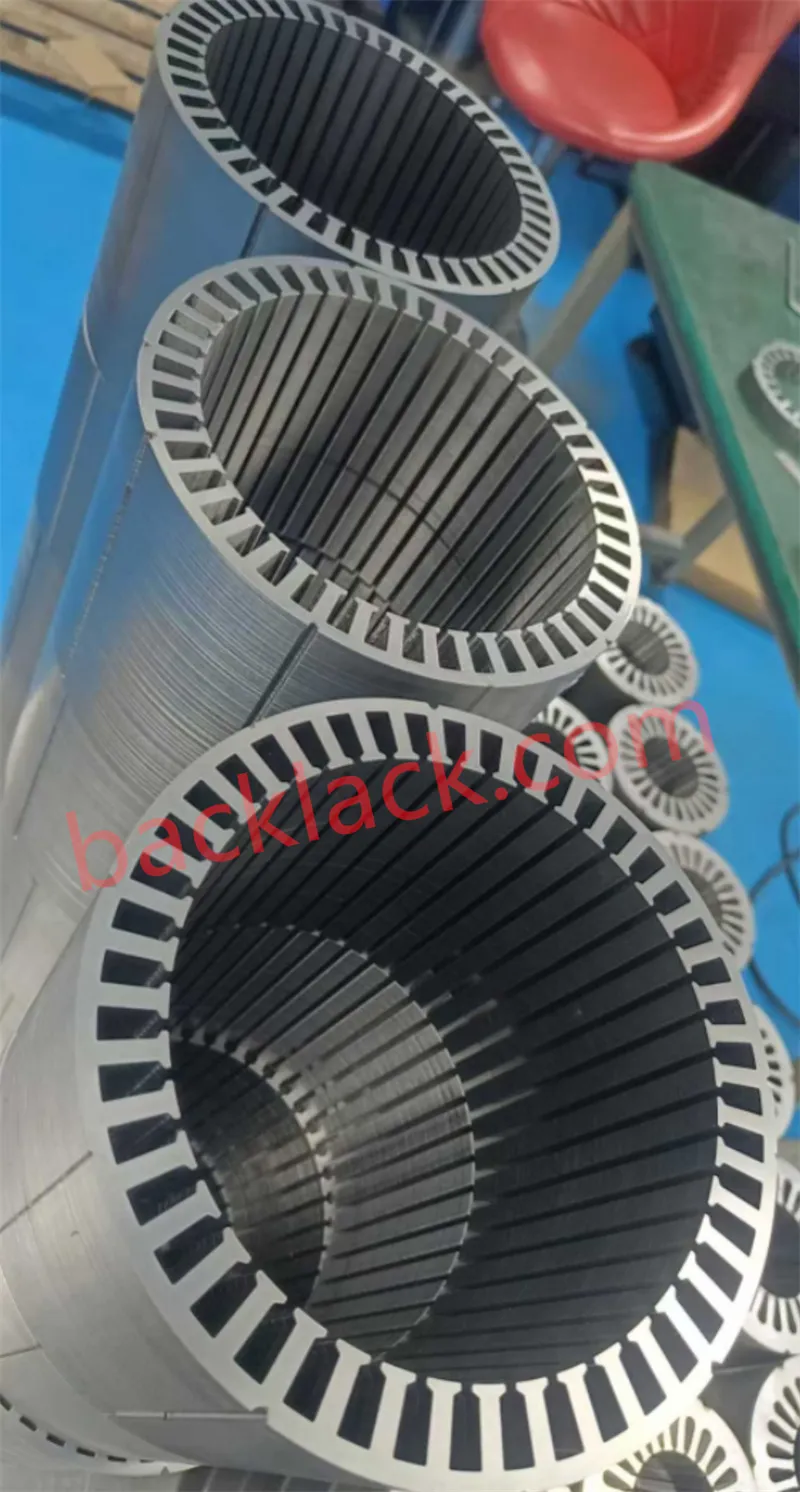

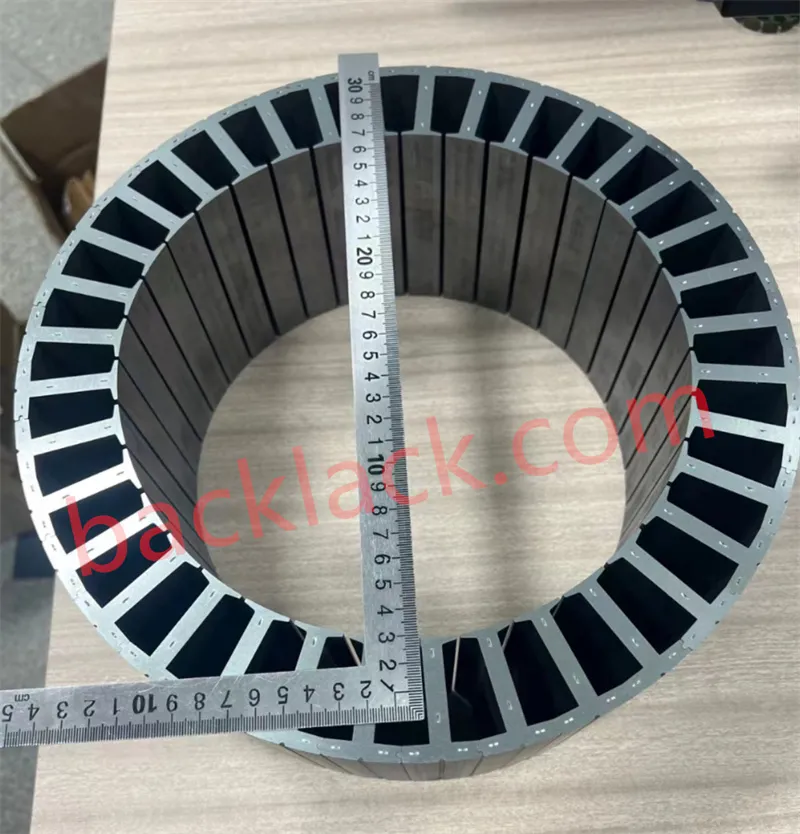

We offer end-to-end customization covering all types of stator cores, tailored to diverse scenarios:

| Motor Application | Customization Focus | Typical Tolerance Requirement |

|---|---|---|

| NEV Drive Motors | V-shaped/skewed slot design, ultra-thin silicon steel stamping | ±0.002mm |

| Industrial IE5 Motors | Non-standard stack height, slot pitch optimization | ±0.005mm |

| Household Smart Appliance Motors | Cost-controlled custom slot counts, compact size | ±0.01mm |

| Aerospace/Marine Motors | Amorphous alloy compatibility, vacuum stamping | ±0.0015mm |

2. Core Advantages of China-Based Custom Stator Core Stamping (Our Competitive Edge)

As a China-focused supplier, we leverage local industrial clusters, full-chain integration, and flexible production to deliver custom solutions that outperform overseas competitors. The table below highlights our key advantages vs. international counterparts:

| Advantage Category | Our Capabilities | Overseas Supplier Benchmark | Client Value Gain |

|---|---|---|---|

| Rapid Prototyping | 7-day prototype delivery via 3D-printed die inserts | 4-6 week prototype lead time (Europe/US) | Cuts motor R&D cycle by 30% |

| Cost Efficiency | Custom die costs 35% lower than European suppliers; silicon steel sourced directly from Baosteel (10% material cost reduction) | 20-40% premium on custom orders (Japan/Korea) | Reduces overall custom core cost by 25% |

| Full-Chain Integration | In-house die R&D, silicon steel pre-processing, stamping, magnetic testing, and bonding | Fragmented supply chain (multiple vendors for die/materials/stamping) | Eliminates 3+ middle links, shortens delivery by 40% |

| Flexible Production | Switch between 5+ custom stator designs in 2hrs; support 1-piece prototyping to 500k-piece mass production | Minimum 500-piece custom MOQ (most overseas factories) | Adapts to motor design iteration and phased production needs |

2.1 Deep Dive into Key Advantages

2.1.1 Full-Chain Vertical Integration

We’ve built a closed-loop system from raw material sourcing to finished product delivery:

- Material Direct Procurement: Strategic partnerships with Baosteel and Nippon Steel enable custom silicon steel grade selection (e.g., 0.15mm ultra-thin 35W250 for NEVs) with 3-day material lead time

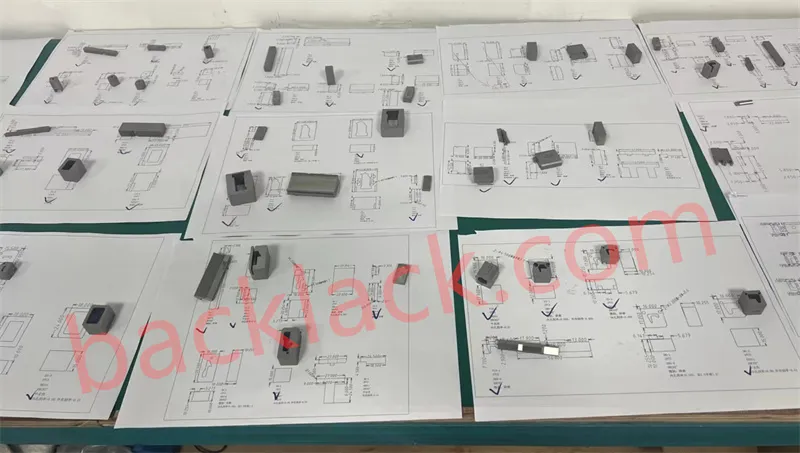

- In-House Die R&D: Our 15-person die engineering team develops custom progressive dies in 10 days (vs. industry average 20 days)

- One-Stop Processing: Combine stamping, deburring, bonding, and magnetic property testing in one facility, avoiding cross-vendor quality inconsistencies

2.1.2 Local Industrial Cluster Synergy

Rooted in the Yangtze River Delta motor industry cluster, we benefit from proximity to:

- Precision die manufacturers (1hr delivery of die components)

- Third-party testing labs (same-day magnetic property certification)

- JIT logistics networks (direct delivery to client motor assembly lines, cutting inventory costs by 20%)

3. Our Custom Stator Core Stamping Workflow (Client-Centric Process)

Unlike rigid mass-production lines, our workflow is tailored to client needs at every stage:

- Demand Co-Creation: Our R&D team collaborates with clients to clarify performance targets (core loss, power density) and production constraints (lead time, budget)

- Custom Material & Die Design: Select optimal materials and design dies for unique slot shapes/stack heights; provide die simulation reports for client validation

- Flexible Stamping: Deploy servo-driven presses (1,200 strokes/min) with real-time tolerance monitoring; switch between prototype and batch production seamlessly

- Custom Finishing: Offer welding/riveting/adhesive bonding per client specs; achieve <0.008mm burr size for high-speed motors

- Transparent Quality Control: Share real-time inspection data via a client portal (3D scanning, magnetic permeability testing); provide third-party certification before delivery

- Phased Delivery: Support 7-day prototype delivery, 15-day small-batch delivery, and JIT mass production for automotive clients

4. Addressing Custom Stamping Challenges (Our Problem-Solving Capabilities)

4.1 Balancing Customization with Cost & Lead Time

- Die Component Reuse: Repurpose 40% of die parts for similar client designs, cutting die costs by 40%

- Shared Material Pools: Maintain a stock of common silicon steel grades to reduce lead time for small-batch custom orders by 50%

4.2 Ensuring Batch Consistency

- Magnetic Property Matching: Pre-test each material batch to ensure permeability variance <2% across production runs

- Die Wear Monitoring: Real-time sensors track die wear, maintaining tolerance accuracy for 100k+ stamping cycles

5. Future of Custom Stator Core Stamping: Our Roadmap

5.1 Axial Flux Motor Customization

We’re investing in custom stamping processes for radial-slot axial flux stator cores, and 0.1mm amorphous alloy lamination stamping to support next-gen premium NEVs (e.g., NIO ET9-style models)

5.2 Joint R&D Program

Launching a “Client Co-Design Initiative” to embed our stamping expertise into clients’ early motor design phases, optimizing stator geometry to boost performance while cutting production costs

5.3 Global Custom Service Expansion

Establishing a Mexico-based custom stamping facility to serve North American NEV startups, offering localized design support and JIT delivery to avoid trade barriers

Conclusion

For us, custom stator core stamping is more than manufacturing—it’s about translating clients’ motor innovation goals into tangible, high-quality components. As a China-based supplier, our unique advantages in chain integration, cost efficiency, and flexible response set us apart in the global market.

Whether you need a single prototype for a breakthrough EV motor, a small-batch custom stator for industrial retrofitting, or a mass-production JIT solution for household appliances, our team is equipped to deliver a tailored plan that fits your exact needs. Reach out today to start your custom stator core project.

About Youyou Technology

Youyou Technology Co., Ltd. specializes in the manufacture of Self-bonding precision cores made of various soft magnetic materials, including Self-bonding silicon steel, ultra-thin silicon steel, and Self-bonding specialty soft magnetic alloys. We utilize advanced manufacturing processes for precision magnetic components, providing advanced solutions for soft magnetic cores used in key power components such as high-performance motors, high-speed motors, medium-frequency transformers, and reactors.

The company Self-bonding precision core products currently include a range of silicon steel cores with strip thicknesses of 0.05mm(ST-050), 0.1mm(10JNEX900/ST-100), 0.15mm, 0.2mm(20JNEH1200/20HX1200/ B20AV1200/20CS1200HF), and 0.35mm(35JNE210/35JNE230/ B35A250-Z/35CS230HF), as well as specialty soft magnetic alloy cores including Hiperco 50 and VACODUR 49 and 1J22 and 1J50.