-

Lower Losses

Compared to interlocking and welding, bonding has not short cuts between the single sheets. Better magnetical properties and lower losses are the result.

-

Reduces Noise

The single sheets are glued together tightly which reduces vibration and noise. A good approach to address the higher requirements.

-

Improves Thermal Conductivity

The full area bonding improves thermal conductivity within the stack because Bonding varnish/Backlack has a better thermal conductivity than the air we have from interlocking or welding.

Bonding varnish/Backlack

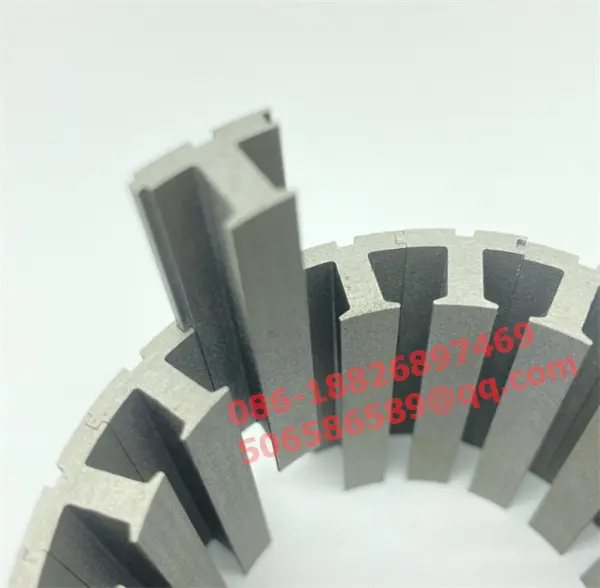

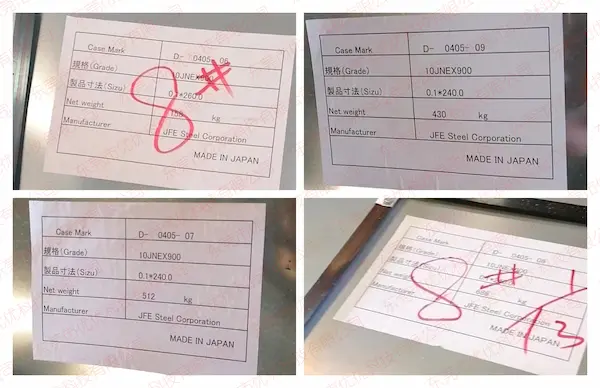

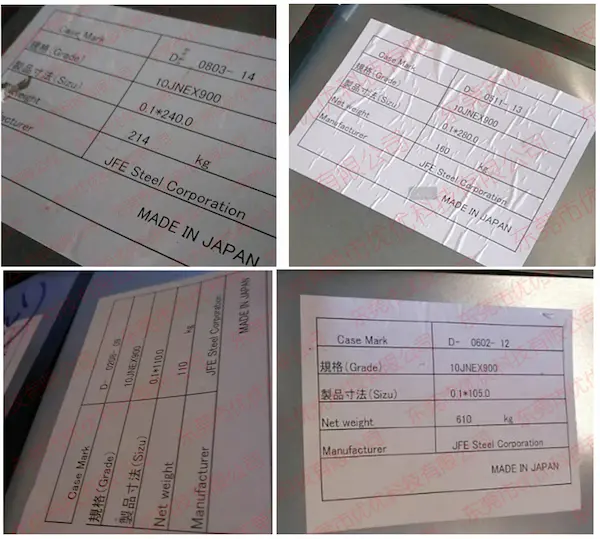

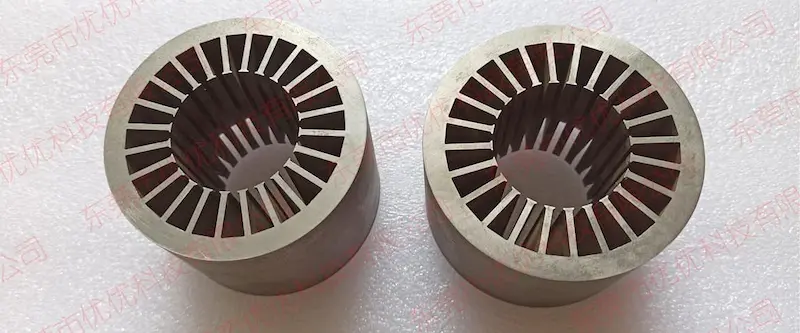

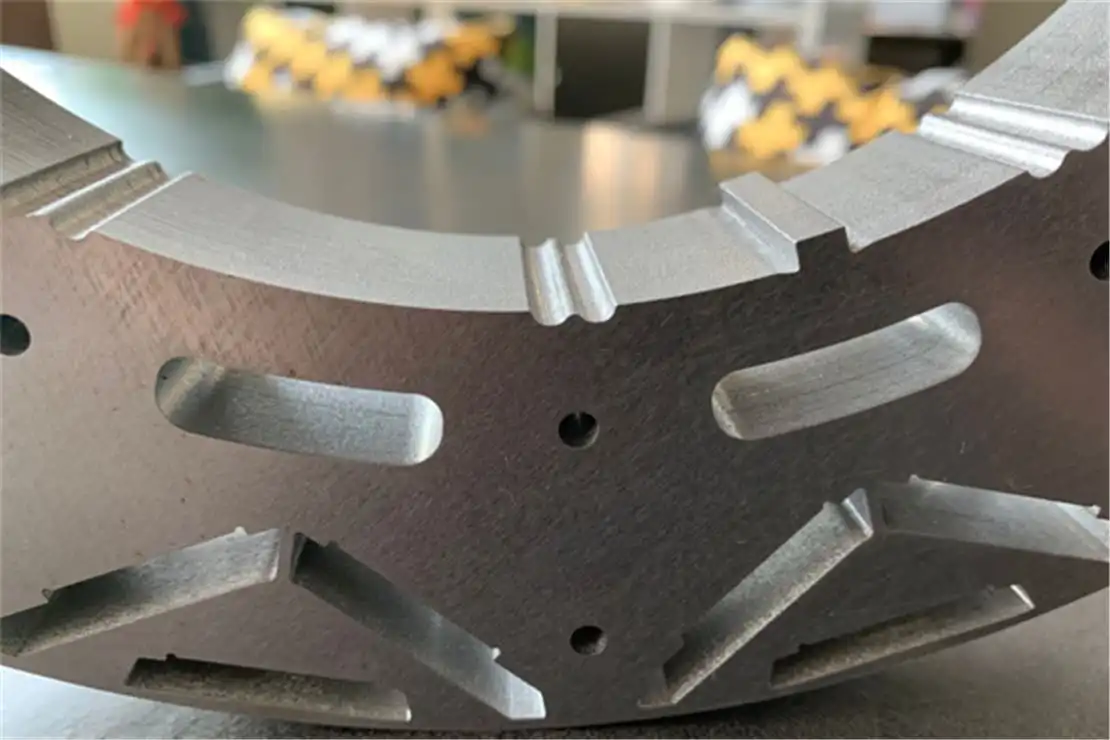

Experience in Manufacturing Supercore 10JNEX900 0.1mm Stators

Regular inventory of over 2000 KGS, width of 25/31/70/94/110/220/235/240/260mm, etc., to meet the needs of customers in different sizes;

PuTian YouYou Technology Co., Ltd. is familiar with the development of high-speed motors and the selection and application of Supercore 10JNEX900 silicon steel, and has a deep understanding of the performance of high-speed motors. Therefore, bonding is the main lamination technology that utilizes ultra core performance. We have more than 10 years of experience in bonding laminations;

For more details about stator bonding technology, please feel free to share your drawings and technical requirements with us at any time. For more detailed questions, please feel free to Contact us.

Bonding varnish/Backlack - the joining technology for perfect lamination stacks!

The stator and rotor cores of electrical machinery are manufactured using thin laminations stacked together in order to minimize eddy current losses. There are several ways to join these laminations, and the most efficient way is to use Backlack.

Enhanced Structural Integrity

Bonding laminations together creates a unified and robust structure, minimizing the risk of mechanical failure and ensuring long-term reliability.

Reduced Eddy Current Losses

Proper stator and rotor core stacks bonding minimizes eddy current losses, optimizing energy efficiency and reducing heat generation.

Improved Magnetic Energy Transfer

Bonded laminations contribute to efficient magnetic energy transfer, enhancing the motor's overall performance and energy efficiency.

Thermal Stability

The bonded structure enhances thermal stability, crucial for motors operating in variable temperature environments.

Vibration Reduction

The bonding process reduces vibrations within the motor, leading to quieter operation and extended lifespan.

Cost-Effective

It is a cost-effective solution to reducing the need for additional bonding and enhancing overall motor performance.

Materials Used In Motor Bonding Lamination Stacks

Silicon steel is regarded as an excellent option for electrical steel lamination prototypes. It not only has good corrosion resistance, is lightweight and has high strength, but its good conductivity ensures efficient application in complex electrical systems.

Non-oriented silicon steel materials with a thickness of 0.10/0.20/0.35MM are also very suitable for making prototype laminations due to their excellent tensile strength, durability and excellent electrical properties, showing a high degree of applicability.

As for nickel alloys, their high corrosion resistance, excellent electrical conductivity and relatively low cost make them ideal materials for prototyping laminates, which, combined with their ease of forming, further enhances their usefulness in this field sex.

Lamination Bonding FAQS

How long does it take to prototype a bonded laminate?

The prototyping time for bonded laminates usually takes about 10 days. This duration includes the process of designing, testing, and refining the prototype to meet specific requirements. Efficient prototyping ensures that the final bonded laminate meets quality standards and performance standards within a reasonable time frame.

Which industries use adhesive motor laminates?

Adhesive motor laminates are widely used in industries such as automotive, aerospace, and industrial. It can be used in the manufacture of electric motors, generators, and transformers.

The Backlack adhesive bonding process enhances structural integrity, minimizes vibration, and improves thermal performance, which contributes to efficient and reliable operation in various industrial fields.

What are the important factors to consider when selecting bonding materials?

Factors such as high temperature resistance, mechanical strength, and application requirements are crucial when selecting bonding materials for motor laminations. The material should meet the operational requirements.

How does the choice of bonding material affect motor performance?

The choice of bonding material affects the thermal conductivity, resistance to environmental factors, and overall mechanical strength of the motor. It is crucial to select a material that meets the motor's operational requirements.

What are the other ways to bond motor laminations besides bonding?

In addition to bonding, we also offer rotor and stator lamination stacking including laser welding, TIG welding, MIG welding, riveting, clamping, interlocking, rotor shaft insertion and more.

Superior Adhesive Lamination - Act Now!

Bring unparalleled quality and performance to your products with our advanced lamination bonding solutions. Trust our expertise to enhance structural integrity, reduce vibration and optimize magnetic energy transfer. Contact us now!

You might also be interested in